Custom Metal Fabrication 5 Types.

Common fabrication techniques include cutting, forming, punching, stamping, shearing and welding – you can find out more about these techniques above.

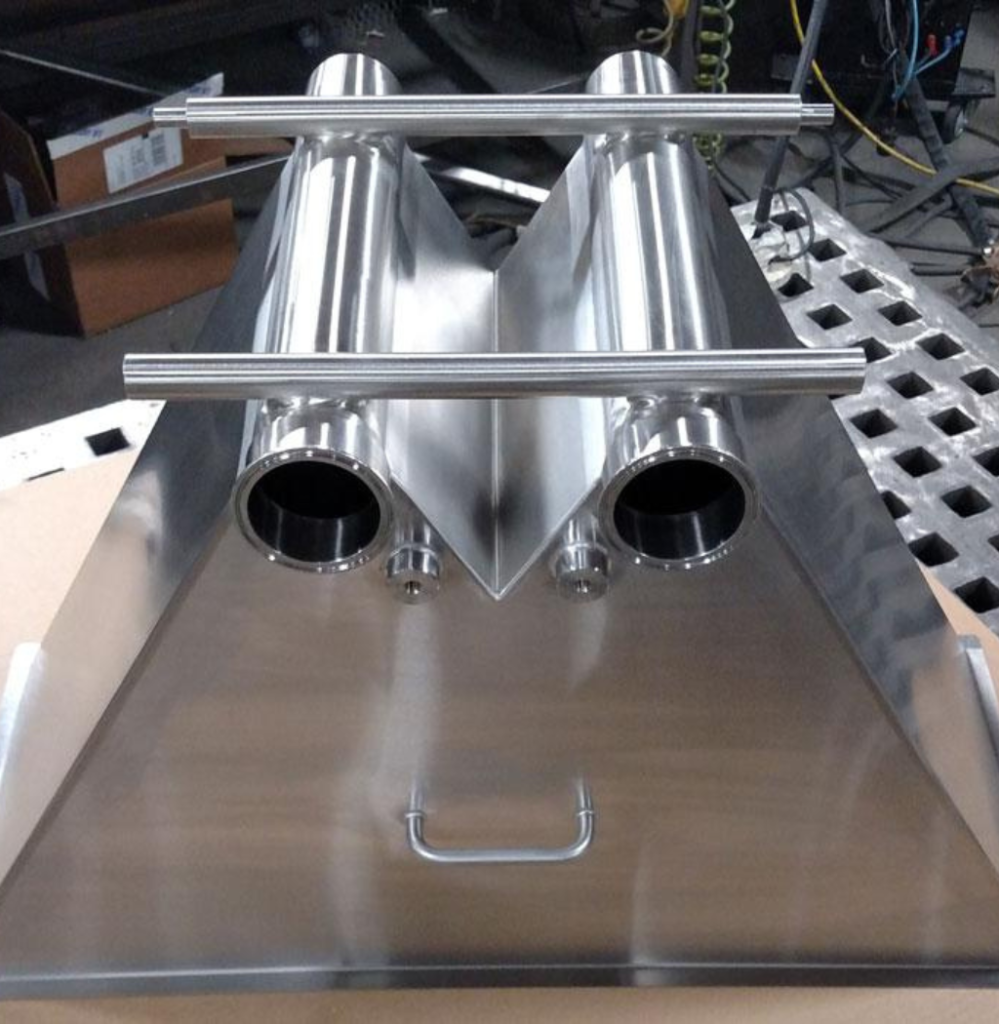

Metal fabrication is a manufacturing process used to shape metal into parts or end products. Most people think of welding when they hear metal fabrication, but welding is just one process metal fabricators use. We use several techniques to shape sheet metal into a part or good

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials..

A custom is defined as a cultural idea that describes a regular, patterned behavior that is considered characteristic of life in a social system. Shaking hands, bowing, and kissing—all customs—are methods of greeting people. The method most commonly used in a given society helps distinguish one culture from another.

LASER CUTTING

Custom metal fabrication employs a wide range of industrial tools and equipment that can cut, bend, roll and join metal into complex shapes and assemblies. The most common metals used are carbon steel, stainless steel, aluminum and copper.

Carbon steel is the the most used material for metal fabricators and is the predominant metal for industrial purposes

Custom metal fabrication employs a wide range of industrial tools and equipment that can cut, bend, roll and join metal into complex shapes and assemblies. The most common metals used are carbon steel, stainless steel, aluminum and copper.